Capacity: 10L-3000L etc Heating method: Electric heating, steam heating, thermal oil heating, hot water circulation Materials: SS304/SS316 Application: Pharmaceutical, Health products, Biological,Food, Chemical Solvent: Inorganic solvents include water, dilute acid, and dilute alkali; organic solvents include ethanol, hexane, ether, chloroform, acetone, and petroleum ether.

1000L Solvent Extraction Equipment

Extraction and concentration equipment is a kind of equipment suitable for extracting and concentrating the effective ingredients of Chinese herbal medicine and various plants, and can realize solvent recovery and aromatic oil collection. It is particularly suitable for hospitals, pharmaceutical factories, and scientific research units to develop new products and small-batch production.

Various extraction equipment In many fields such as chemistry, biology, and pharmaceuticals, extraction technology plays a vital role. Extraction, in simple terms, is the process of transferring the target substance from one solvent to another by some means by using the difference in solubility of the substance in two immiscible solvents.

The working principle of the extraction equipment is based on the difference in solubility of the substance in two immiscible solvents. Through specific operating means, such as stirring, heating or decompression, the equipment can effectively transfer the target substance from the original solvent to another solvent to achieve the purpose of extraction. Different types of extraction equipment have different working principles and characteristics to meet the needs of various application scenarios.

Technical parameters

Model | Volume | Heat power | Stirring | Condensation | Cooler | Vacuum |

SE-10 | 10L | 8kw | 0.20kw | 2.0㎡ | 0.3㎡ | 1.5kw |

SE-50 | 50L | 12kw | 0.55kw | 3.0㎡ | 0.5㎡ | 1.5kw |

SE-100 | 100L | 18kw | 0.55kw | 3.5㎡ | 0.5㎡ | 1.5kw |

SE-200 | 200L | 24kw | 0.55kw | 4.0㎡ | 0.8㎡ | 3.0kw |

SE-500 | 500L | 36kw | 1.5kw | 4.2㎡ | 1.0㎡ | 3.0kw |

SE-1000 | 1000L | 48kw | 2.2kw | 5.2㎡ | 1.0㎡ | 5.5kw |

SE-2000 | 2000L | 72kw | 3.0kw | 8.0㎡ | 1.5㎡ | 5.5kw |

SE-3000 | 3000L | 108kw | 5.5kw | 8.0㎡ | 1.5㎡ | 7.5kw |

Heating method:Electric heating, steam heating, thermal oil heating, hot water circulation

Vacuum:-0.06~ -0.09 (Mpa), Jacket pressure: 0-0.3 (Mpa)

Temperature:Normal temperature -110℃, concentration temperature 40-65℃

Material:SS304/ SS316

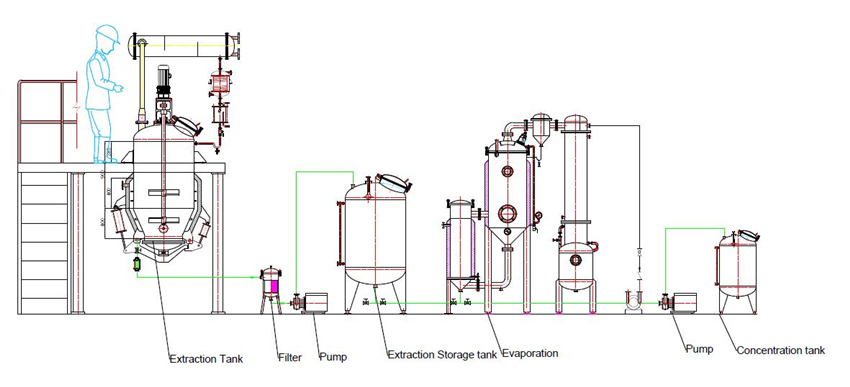

Solvent extraction equipment mainly includes the following key equipment:

Extraction tank: The extraction tank is the main equipment for ethanol extraction. It is used to hold Chinese medicinal materials and ethanol solvents, and promotes the dissolution and extraction of effective ingredients of Chinese medicine by heating and stirring. The extraction tank usually has a jacket or coil heating function to ensure temperature control during the extraction process, and has good sealing performance to prevent ethanol volatilization and external contamination.

Concentrator: The extracted solution needs to be concentrated to increase the concentration of the active ingredients. The concentrator removes part of the solvent (ethanol and water) in the solution by heating and vacuum evaporation to obtain a concentrated solution. The selection of the concentrator should be determined according to the processing volume, the properties of the solution and the required degree of concentration.

Separator: During the ethanol extraction process, some insoluble impurities or precipitates may be produced. The function of the separator is to separate these impurities from the solution to ensure the purity of the extract. Common separation equipment includes filters and centrifuges. The filter intercepts impurities through a screen or filter material, while the centrifuge uses centrifugal force to separate impurities from the solution.

Liquid storage tank: used to store the solution after extraction. The liquid storage tank is usually made of stainless steel or other corrosion-resistant materials to ensure the stability and safety of the solution. The liquid storage tank should also have appropriate stirring and heating functions to maintain the uniformity and temperature control of the solution.

Solvent recovery equipment: Solvent recovery equipment is a new type of efficient distillation equipment used for separation, purification and recovery of organic solvents. For example, a rotary distillation machine is a continuous distillation process that applies rotary distillation technology to industrial production, with the characteristics of high efficiency and low energy consumption. The rotary distillation machine consists of one or more high-speed rotating rotors, and the gas and liquid are transferred through the rotor in a reverse spray manner. It is suitable for the recovery of various organic solvents such as ethanol, methanol, acetone, and product separation and purification.

Ethanol extraction equipment can process a variety of materials, mainly including the following categories:

Chinese medicinal materials: such as ginseng, astragalus, angelica, etc., can extract alkaloids, flavonoids, glycosides and other effective ingredients, which are used in the production of Chinese medicine preparations, health products, etc.

Plant raw materials: plants such as mint, rose, lavender, etc., can be extracted through ethanol to extract their volatile oils, aromatic substances, etc., which are used in spices, cosmetics, food additives and other fields.

Natural pigment raw materials: such as gardenia, safflower, turmeric, etc., can extract natural pigments such as gardenia yellow, safflower red, curcumin, etc., which are used for coloring food, medicine, and cosmetics.

Microbial fermentation products: Metabolites produced by certain microbial fermentation, such as antibiotics, enzymes, etc., can also be extracted and separated by ethanol extraction equipment for further purification and processing.

Animal tissues: such as animal livers, glands, etc., can extract hormones, bioactive peptides and other substances, which are used in biopharmaceuticals and other fields.

Application of Centrifuge Machine in Citrus Esse

The Difference Between Rotary Evaporator And Mol

Stainless Steel Mixing Equipment

Contact: Project Manager

Phone: +86-18120438367

Tel: +86-18120438367

Email: info@tycoretech.com

Add: No. 1, Optics Valley Avenue, East Lake New Technology Development Zone, Wuhan, Hubei, China

We chat